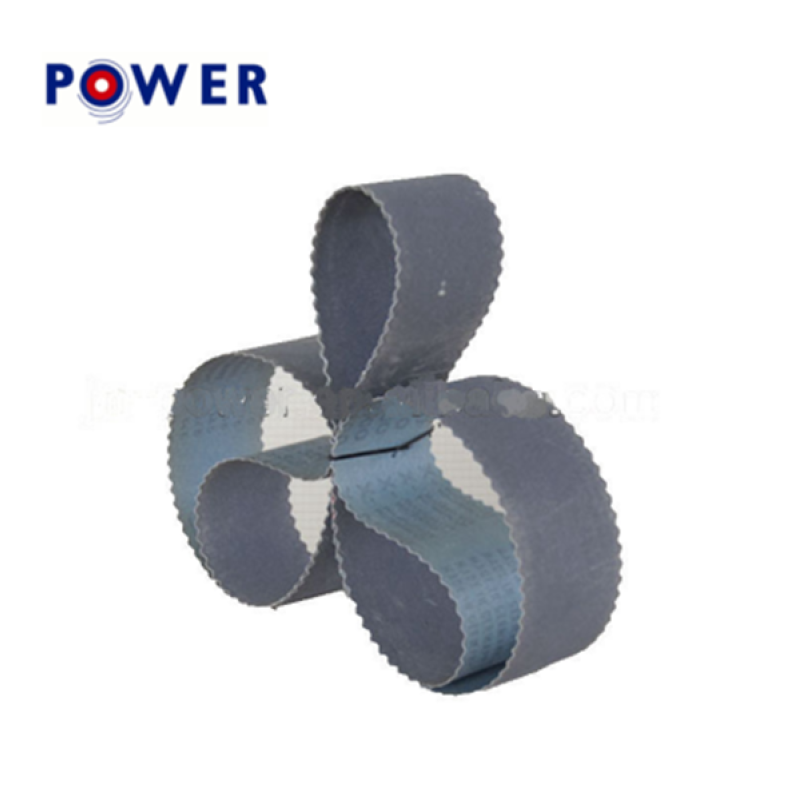

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;3.There are more than one sorts, duration and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature perfor

Contact Now

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;Three. there are more than one sorts, duration and styleCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and styleProduct use:Shipping photos:

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contact Now

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistancePackaging & Shipping 1. Outside package: Standard export wooden cases 2.

Contact Now

Product descriptionCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: Outside package: Standard export wooden cases.Inner package: Stretch film.Shipping detail: Within 2-4 weekOur ServicesInstallation service.Maintenance service.Technical support online service provided.Technical files service provided.On-site training service provided.Renew service provided.Product use:Shipping photos:

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

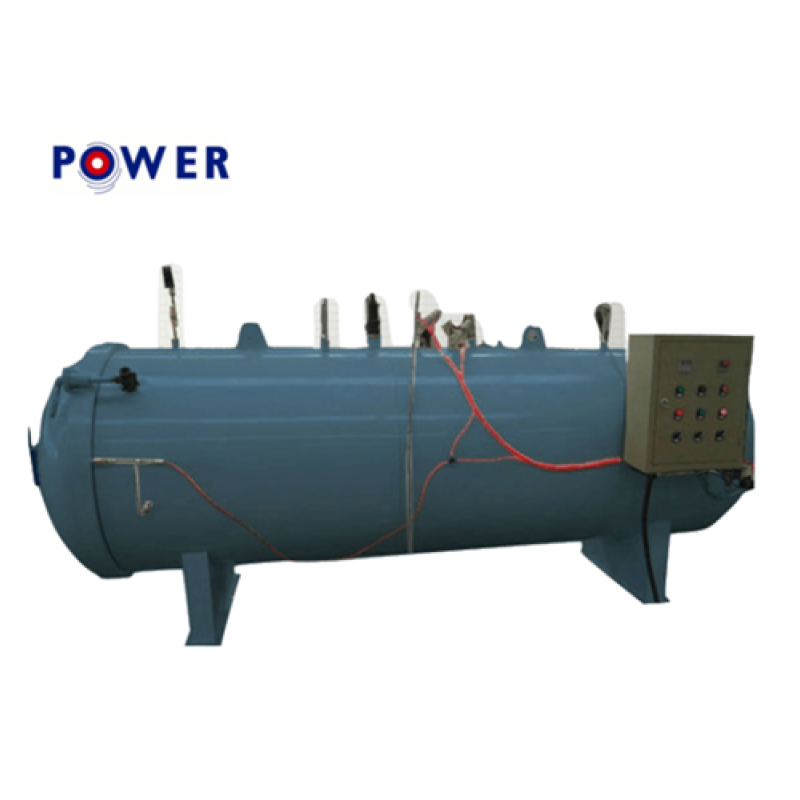

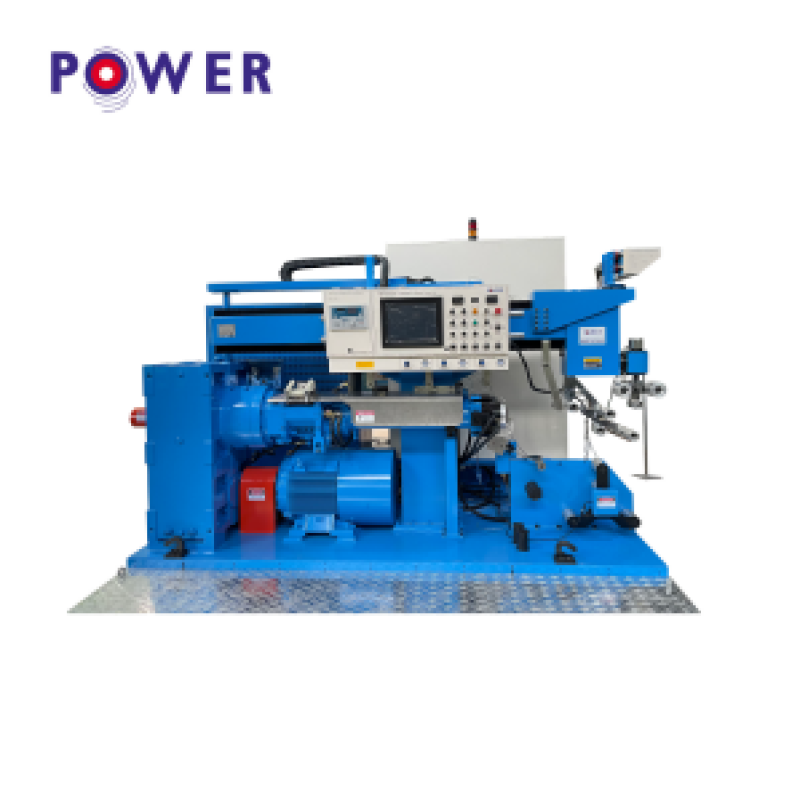

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

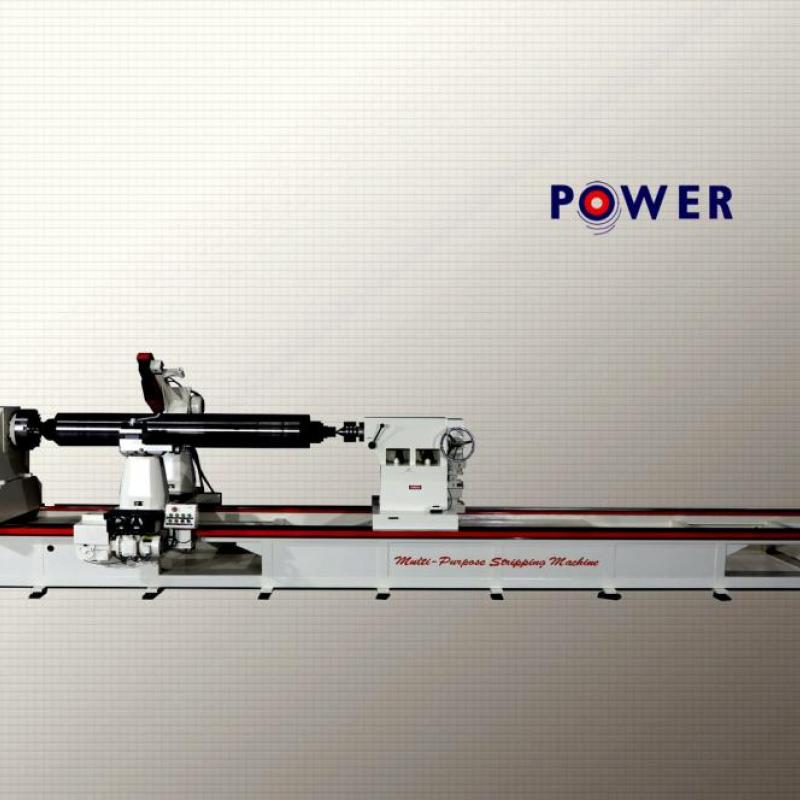

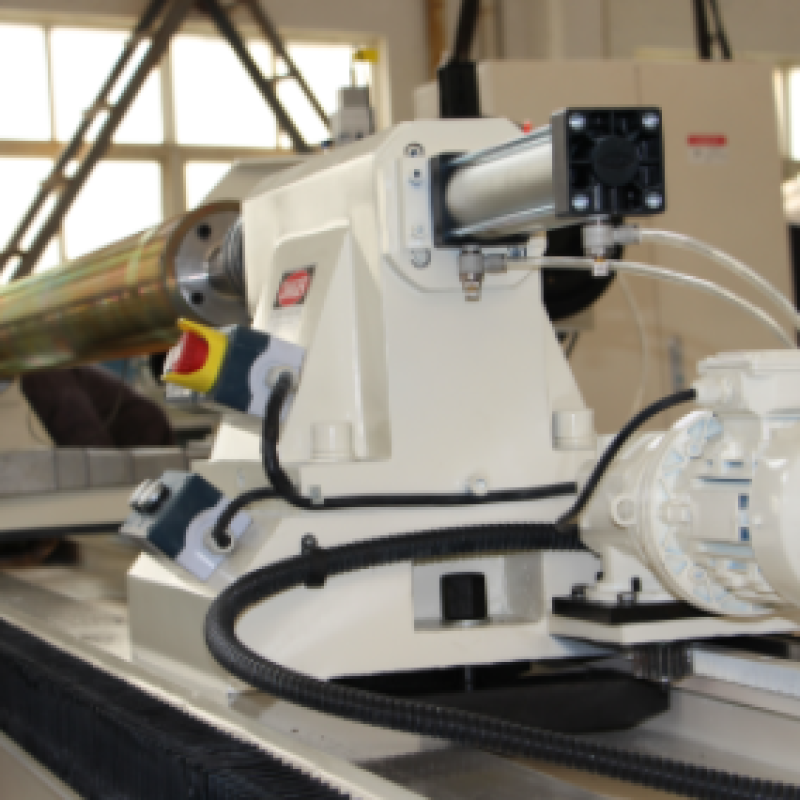

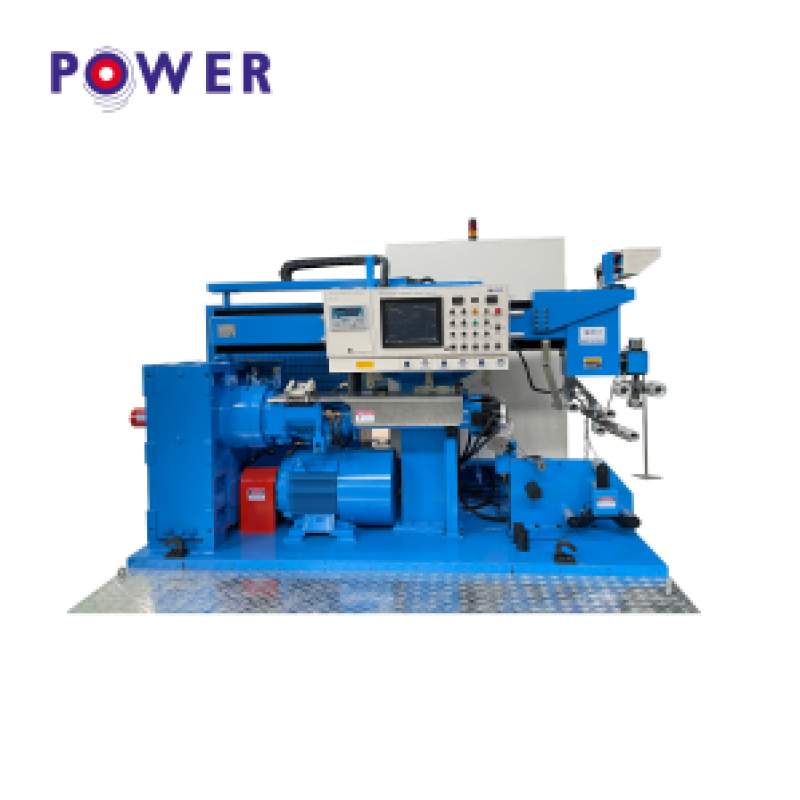

Product description1. The PCM-1250 version is appropriate for renewing Industrial Rubber Rollers.2. Removing vintage rubber through unique ring cutter.3. Replacing the conventional sand-blasting and solvent washing method through superior belt-grinding method.4. Perfectly maintaining the unique dynamic stability of the curler core.5. Giving extra dependable assure for the bonding of the rubber and metallic cores.6. Saving prices and labors with this stepped forward manufacturing system. MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachineProduct description1. The PCM-6040 model is suitable for renewing printing rollers, general industrial rollers and small industrial rubber rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4.

Contact Now

High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistanceApplications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such&n

Contact Now

Packages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersFunctions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackaging & Shipping 1. Outside package: Standard export wooden cases 2. Inner package: Stretch filmShipping detail:Within 2-4 weeksOur Services:1. Installation service.2. Maintenance service.3.

Contact Now

With the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances. numerous operating processes had been introduced to make certain maximum reliable high-quality.With the guideline of excellent first, clients the best, electricity enterprise offers to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of latest base gum and corollary offerings for system manufacturers.Packaging & ShippingPackaging detail: 1.

Contact Now

Functions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersShipping:

Contact Now

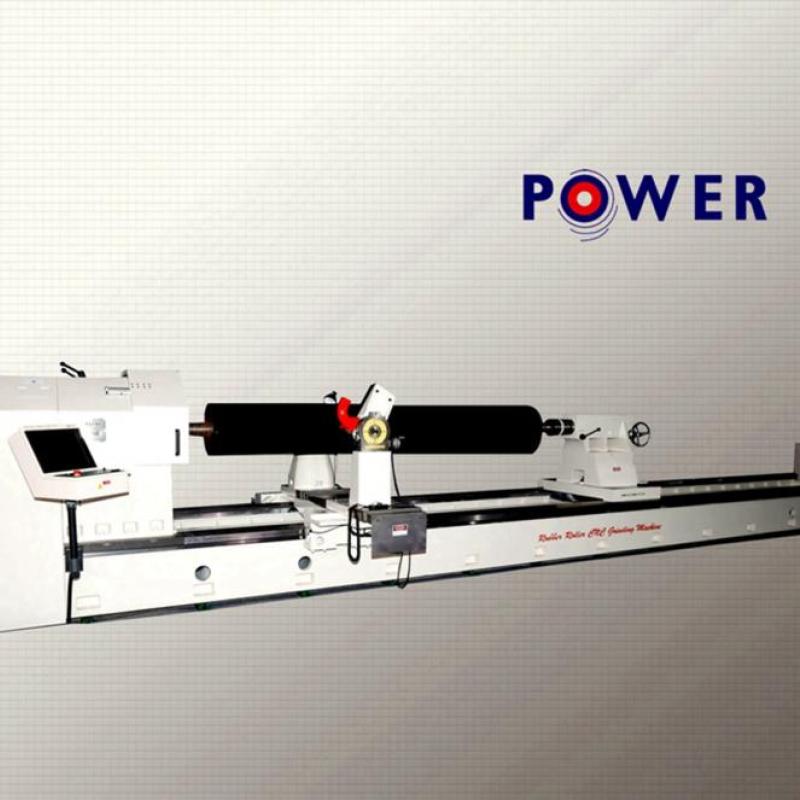

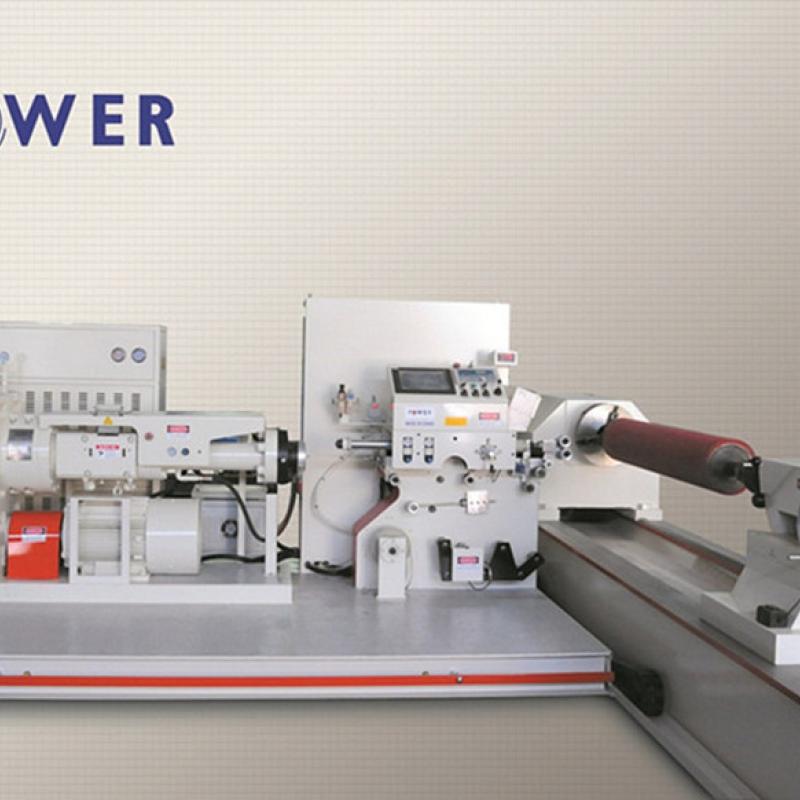

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contact Now

PSM collection rubber curler grinding system is eparticularly designed and synthetic to update the beyond curler processing technique via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond technique to fabricate curler, which the best of curler is tough to attain the requirement of the prevailing standard. The fundamental cause lies withinside the shape of lathe. After all, it isn't always the grinding system; the transferring areas of the large and medium carriage desk are large than that of grinding system.

Contact Now

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersPackaging & Shipping 1. Outside package: Standard export wooden cases 2. Inner package: Stretch filmShipping detail:Within 2-4 weeksOur Services:1. Installation service.2. Maintenance service.3. Technical support online service provided.4.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contact Now

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersShipping:

Contact Now