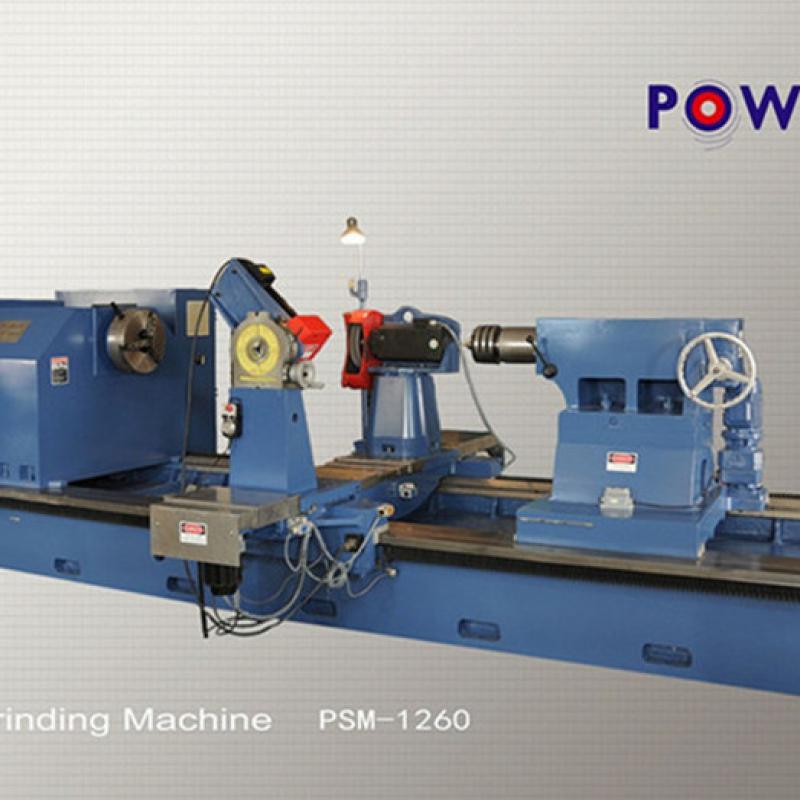

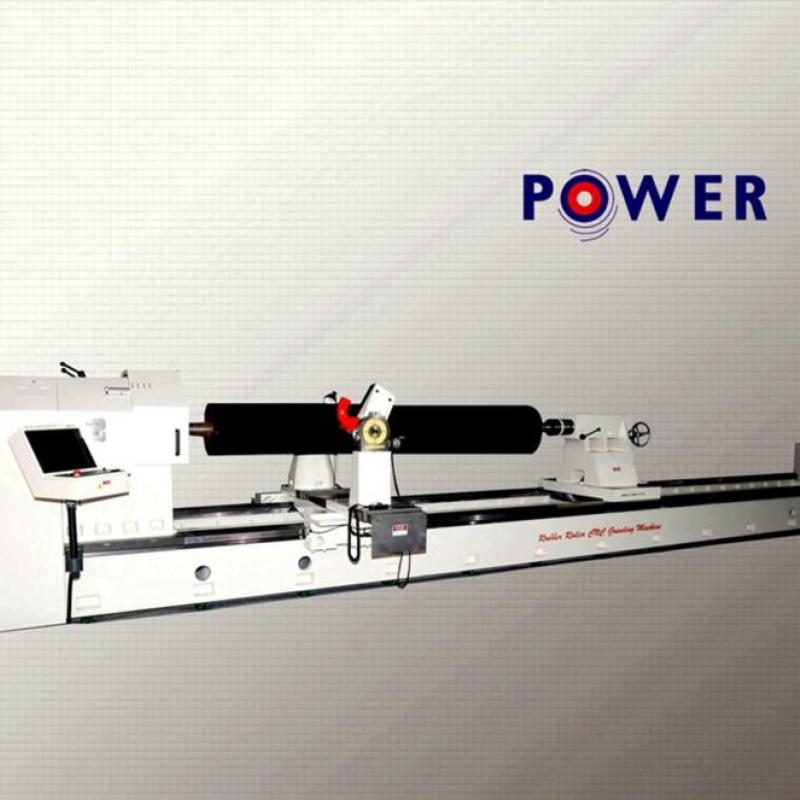

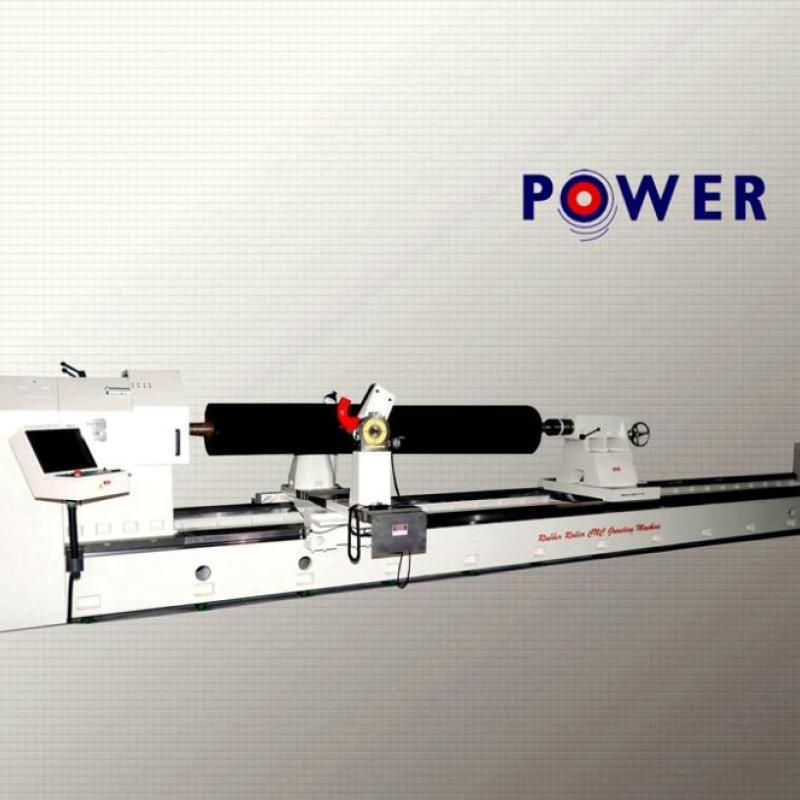

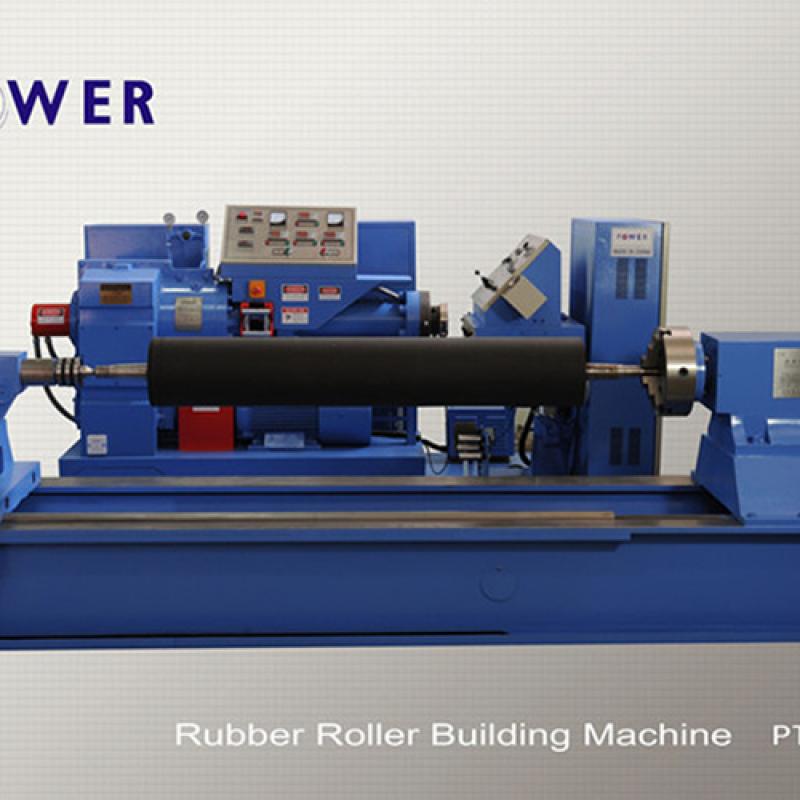

Factory Automatic Cylindrical Roll GrinderThe feature of PSM series Factory Automatic Cylindrical Roll Grinder1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max.

Contact Now

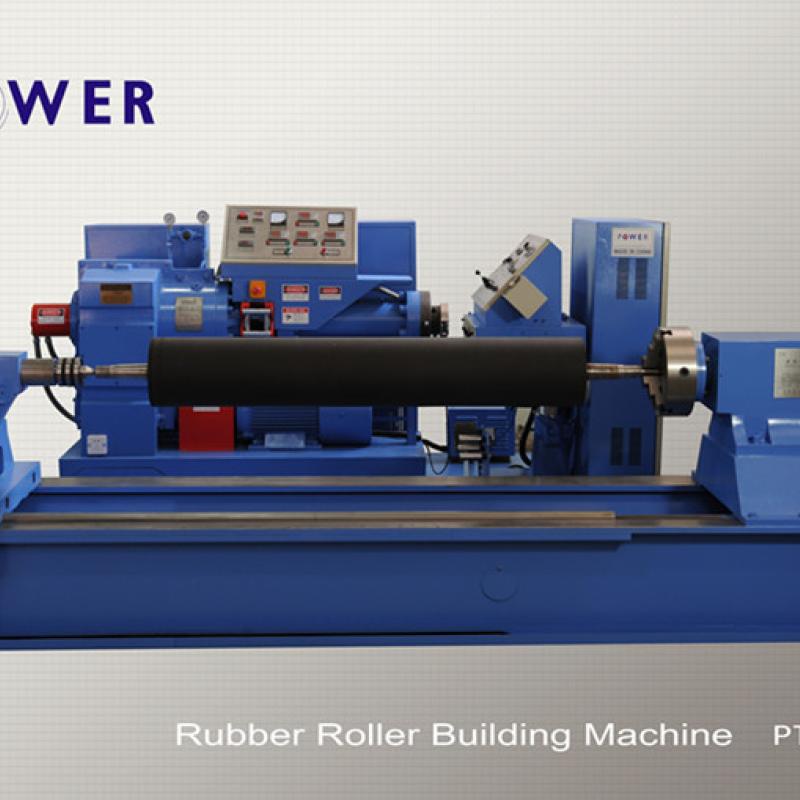

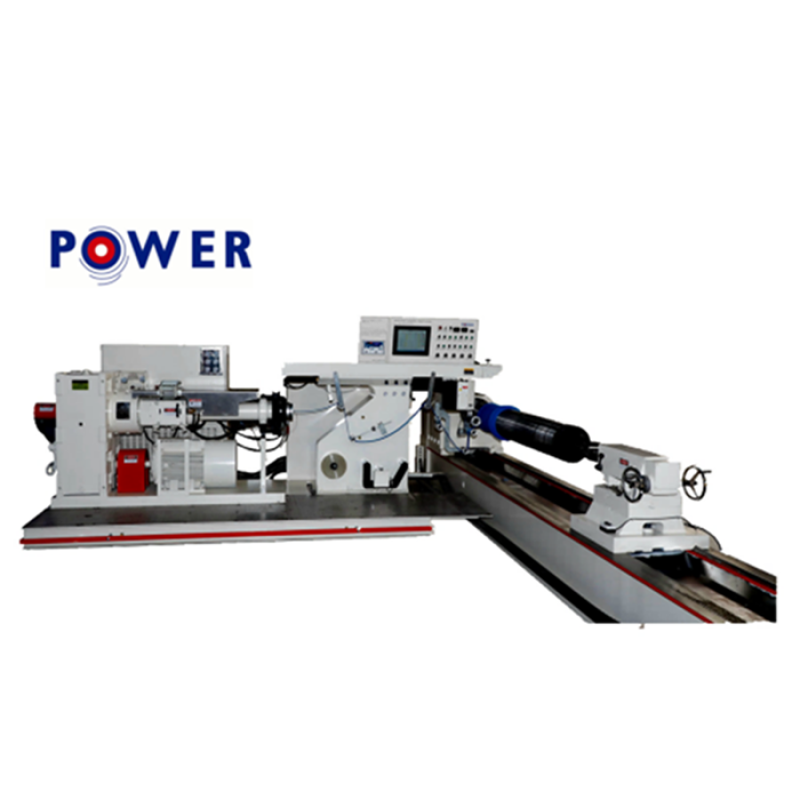

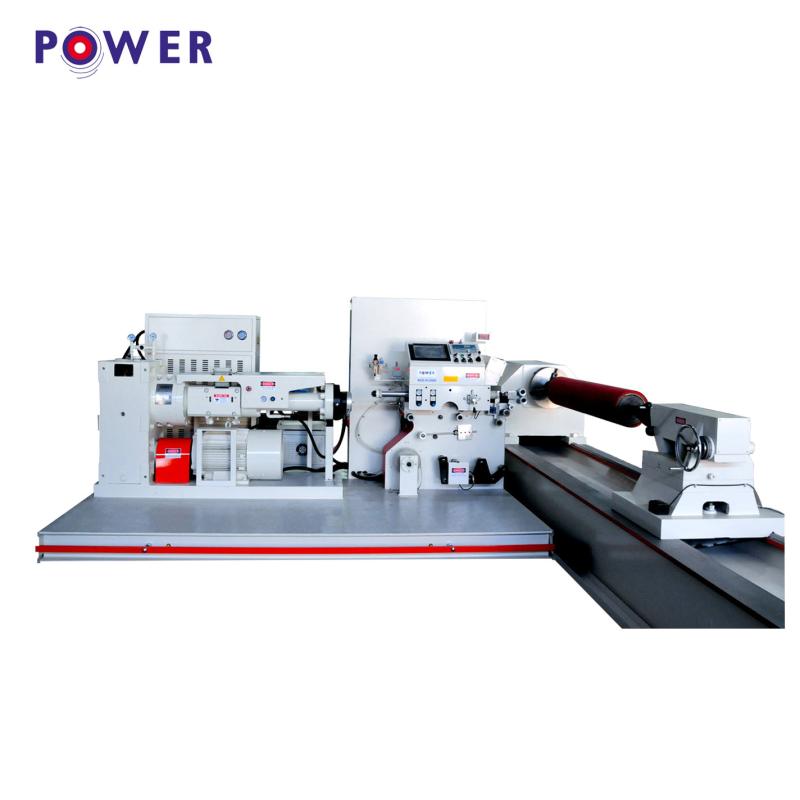

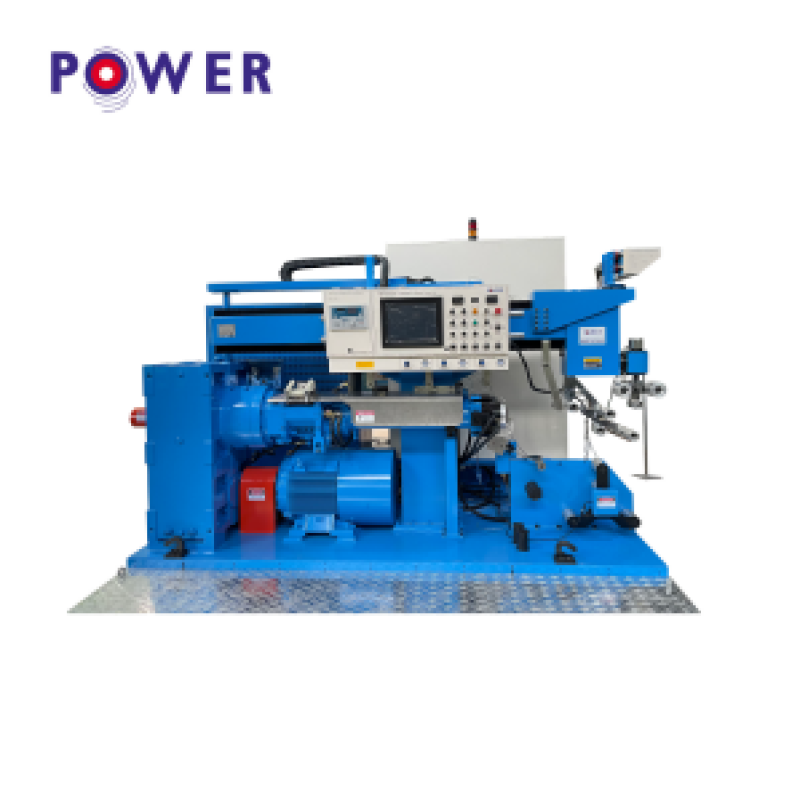

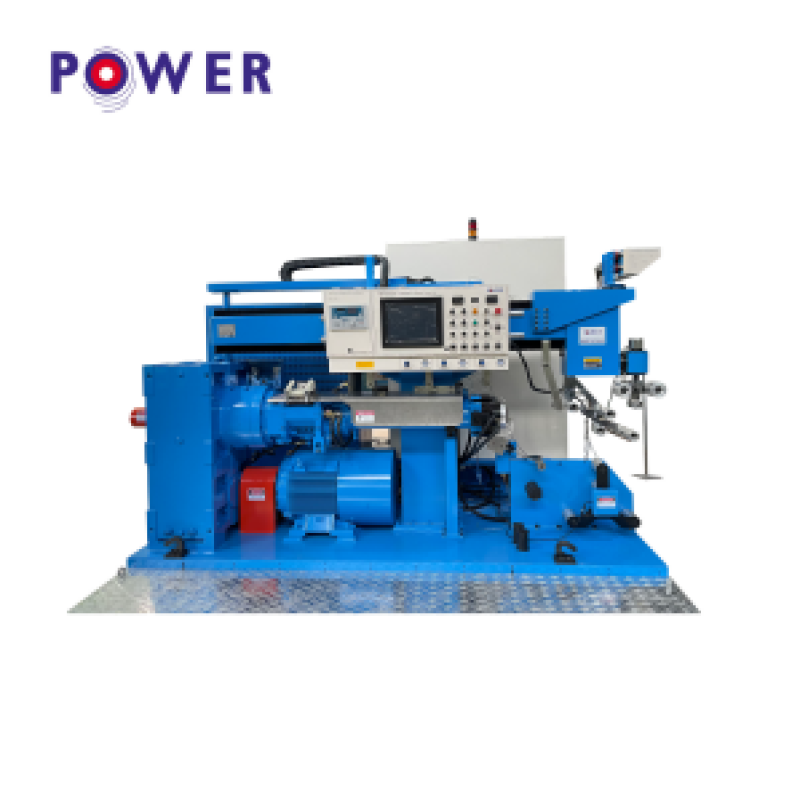

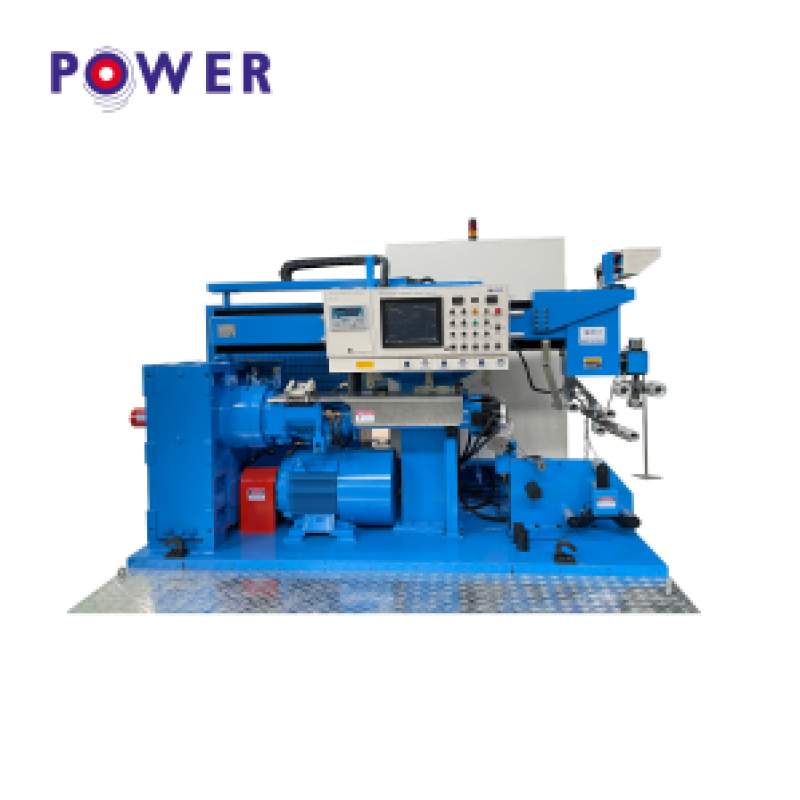

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

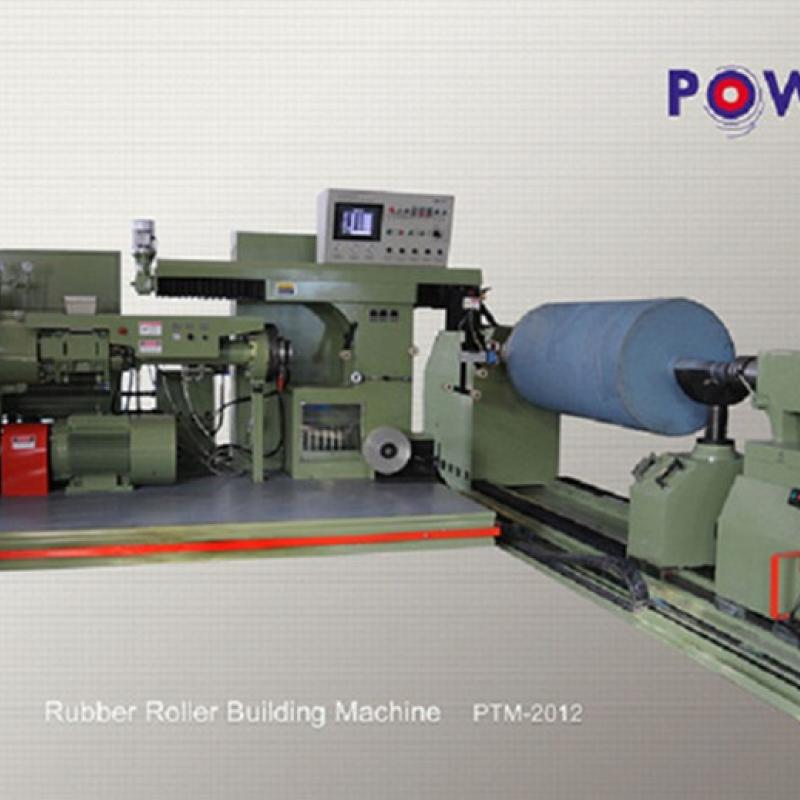

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contact Now

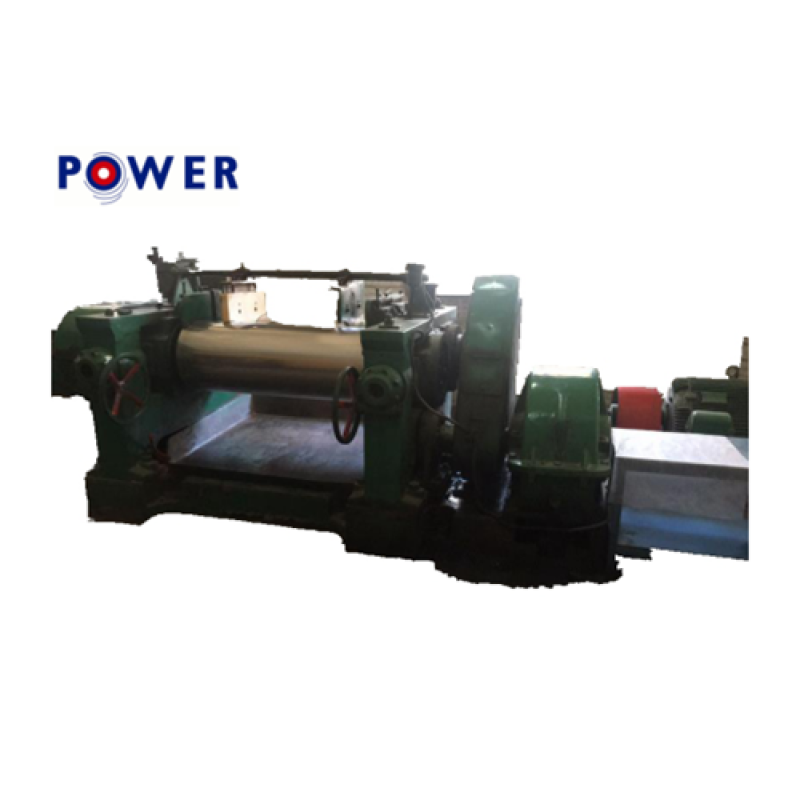

Used Open Rubber Mixing Mill 18" Two Roll / Second-hand Open Rubber Mixing Machine / Used Open Rubber Mixer Mill / Used Open Rubber Mixing MillUsed for rubber mixing and feeding for the next proocess. Second hand used machine with good condition.Product description18" Second-hand Used Rubber Open Mixing MillAbout usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding Machine1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b. motorized tailstock c. variable speed traverse and spindle drives d. front and rear independently operated carriage tables e. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3.

Contact Now

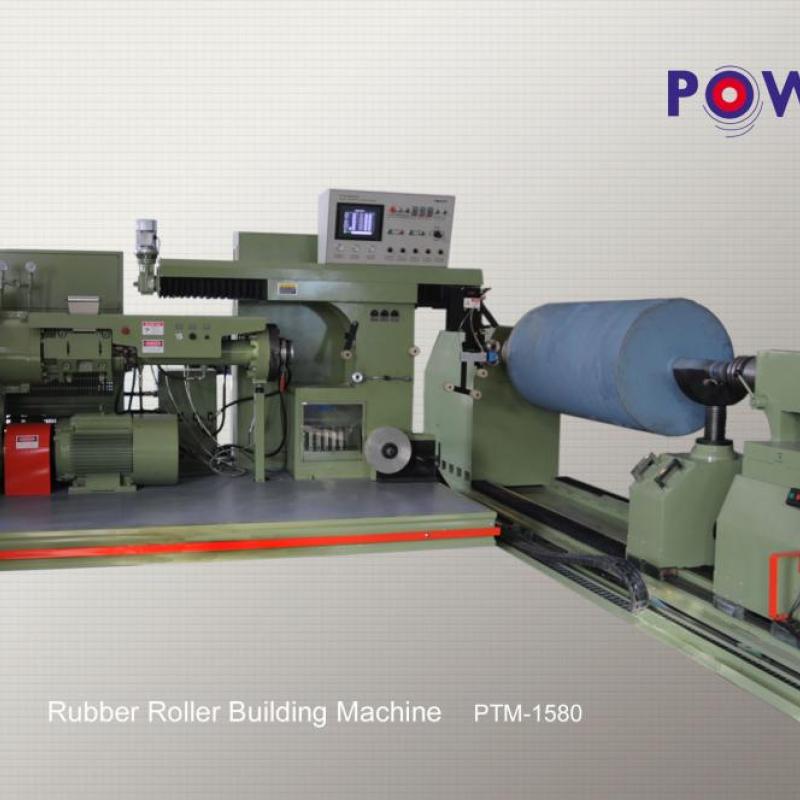

Product descriptionFeatures of PTM-1560 Rubber Roller Wrapping Machine For Paper Industry1. Rubber roller winding machine PTM-1580 model is suitable for paper making industry.2. Our rubber roller winding machine equipped with E350CS power extruder and a complete industrial cooling system.3. The rubber roller winding machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contact Now

Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contact Now

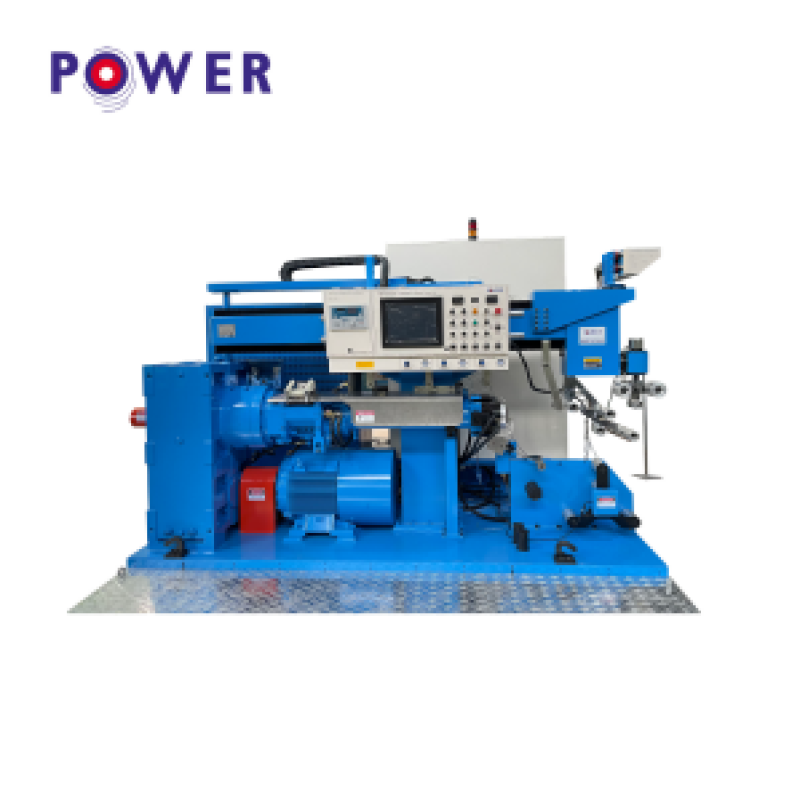

Product descriptionFeatures of PTM-8060 Rubber Roller Coating Machine Price1.Applicable to production of Rubber Rollers in heavy industry, such as transmission rubber rollers in steel and steel deepprocessing industry,textile industry,printing and dyeing industry and so on.2.Equipped with E300CS 76 cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with all hardness.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPT

Contact Now

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contact Now

Product descriptionFeatures of PTM-1080 Steel Textile Dyeing Rubber Roller Wrapping Machine1. Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

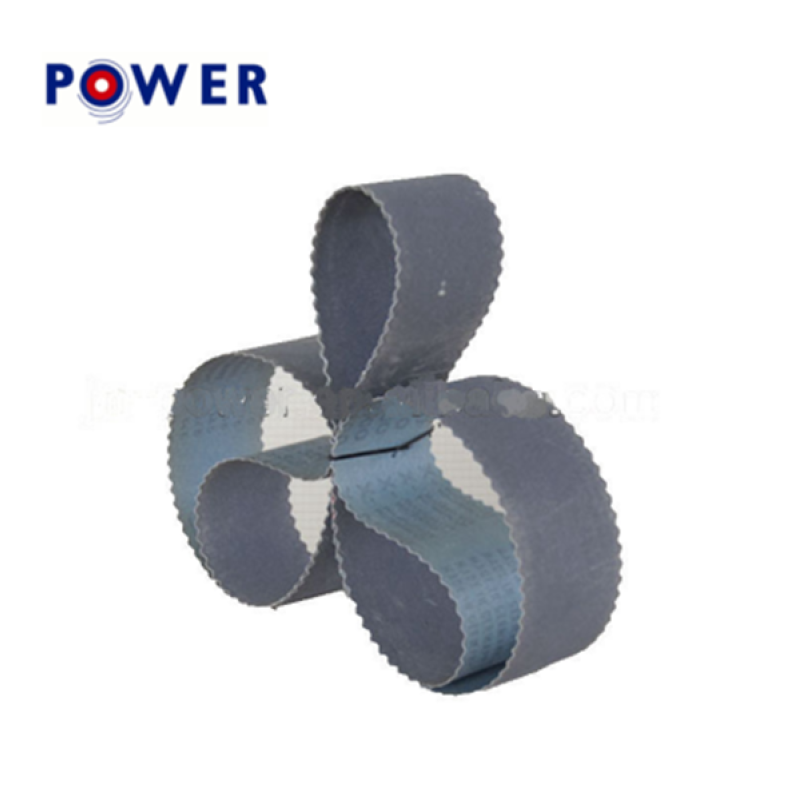

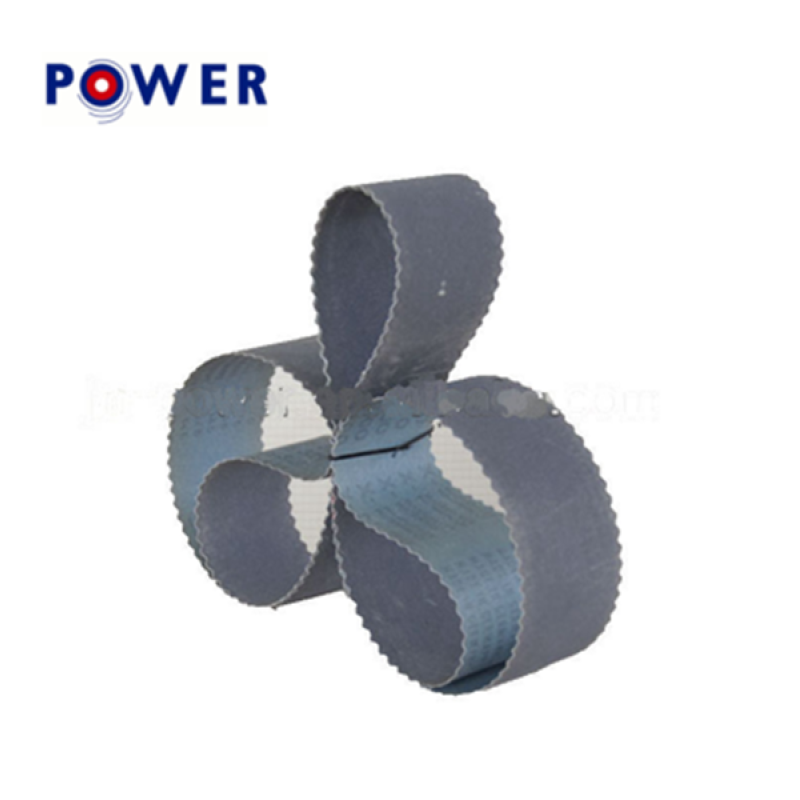

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;3.There are more than one sorts, duration and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;Three. there are more than one sorts, duration and styleCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and styleProduct use:Shipping photos:

Contact Now

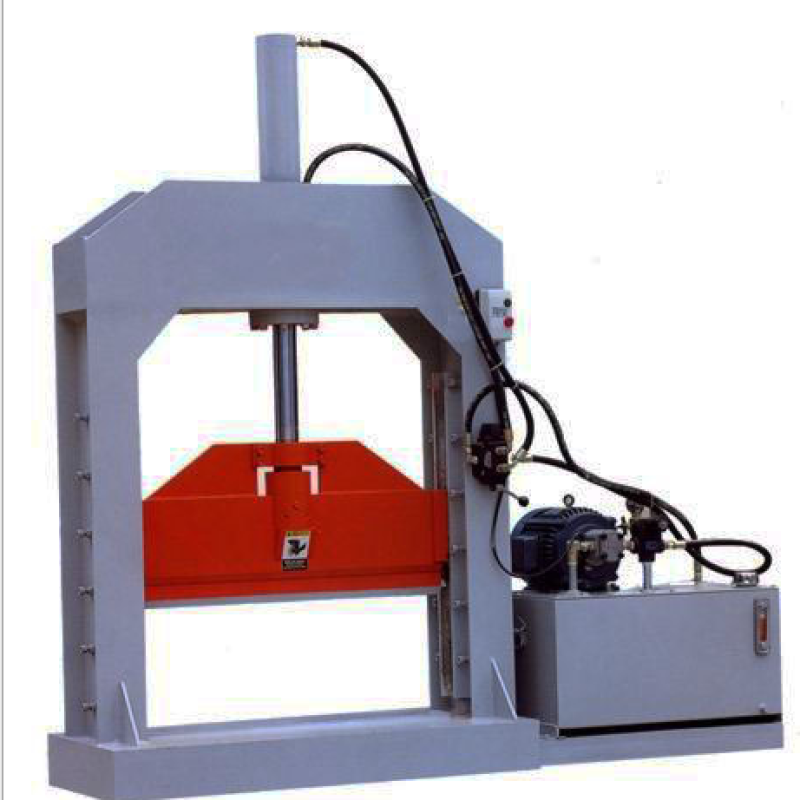

The Hydraulic rubber cutting machine The Hydraulic rubber cutting machine mainly has the cutting glue knife, the machine frame, the work oil cylinder, the base, the auxiliary work table and the hydraulic system, the electrical system and so on part composes, the cutting glue knife base is equipped with the nylon or the soft lead backing plate, protects the cutting knife the blade.Raw gum, with artificial glue in the cutting knife below, and then press the Start button, then the cutting knife in the piston rod driven by the slide along the rack down the rubber material cut.The ra

Contact Now

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding MachineDue to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b.

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contact Now

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber roller Covering Machine PTM-2012 model is suitable for processing paper mill, mine transportation and heavy industrial rolls.2. Our rubber roller building machine equipped with E350CS power extruder and a complete industrial cooling system.3. The Rubber Roller Covering Machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contact Now

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contact Now