Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature perfor

Contact Now

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersPackaging & Shipping 1. Outside package: Standard export wooden cases 2. Inner package: Stretch filmShipping detail:Within 2-4 weeksOur Services:1. Installation service.2. Maintenance service.3. Technical support online service provided.4.

Contact Now

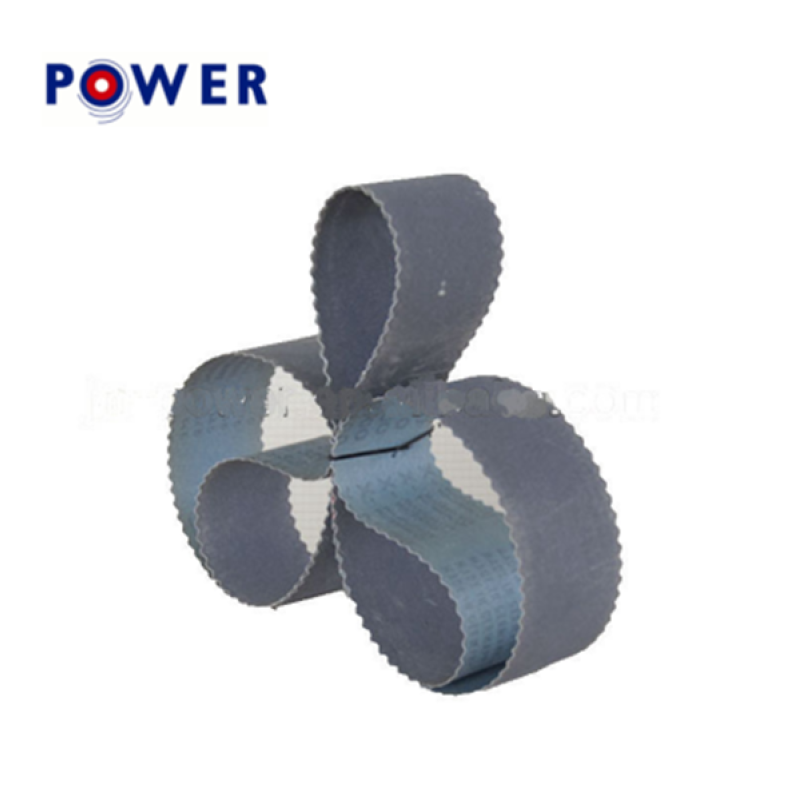

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;3.There are more than one sorts, duration and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;Three. there are more than one sorts, duration and styleCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and styleProduct use:Shipping photos:

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contact Now

High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistanceApplications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such&n

Contact Now

Product descriptionCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: Outside package: Standard export wooden cases.Inner package: Stretch film.Shipping detail: Within 2-4 weekOur ServicesInstallation service.Maintenance service.Technical support online service provided.Technical files service provided.On-site training service provided.Renew service provided.Product use:Shipping photos:

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Packages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersFunctions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackaging & Shipping 1. Outside package: Standard export wooden cases 2. Inner package: Stretch filmShipping detail:Within 2-4 weeksOur Services:1. Installation service.2. Maintenance service.3.

Contact Now

Functions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersShipping:

Contact Now

Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistance Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Shipping:

Contact Now

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistancePackaging & Shipping 1. Outside package: Standard export wooden cases 2.

Contact Now

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersShipping:

Contact Now

Web Press Rubber Roller For PrinterWith the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contact Now

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Special Hickey-Picker Rubber RollerStrength enterprise adopts numerous special glue inventory made in america and germany to manufacture commercial robber rollers. for printing enterprise, there are alcohol plate moisturizing rubber roller, uv inker, rubber roller transmitting and sparing ink.

Contact Now

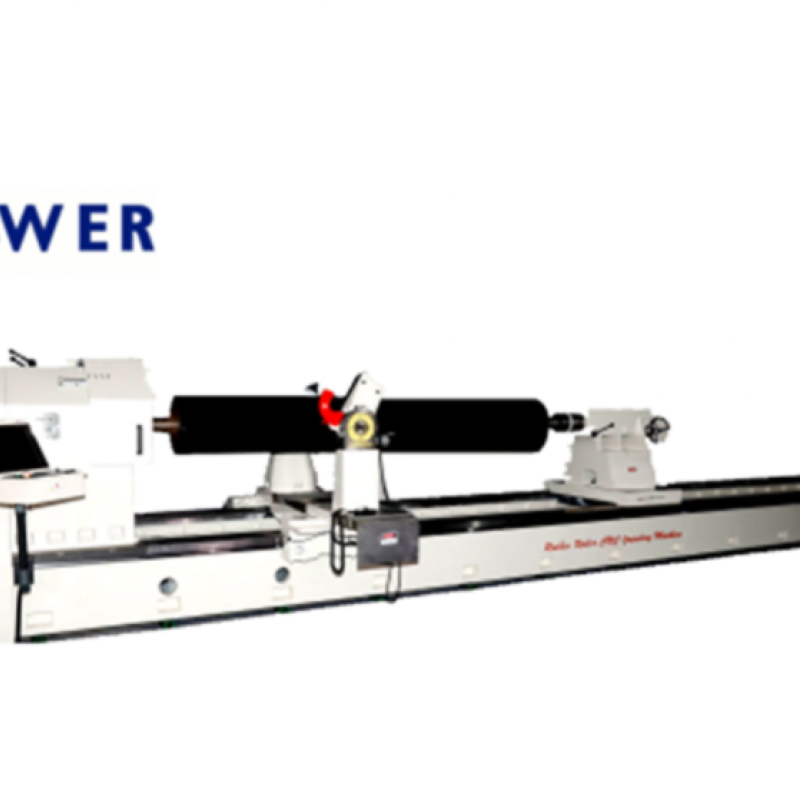

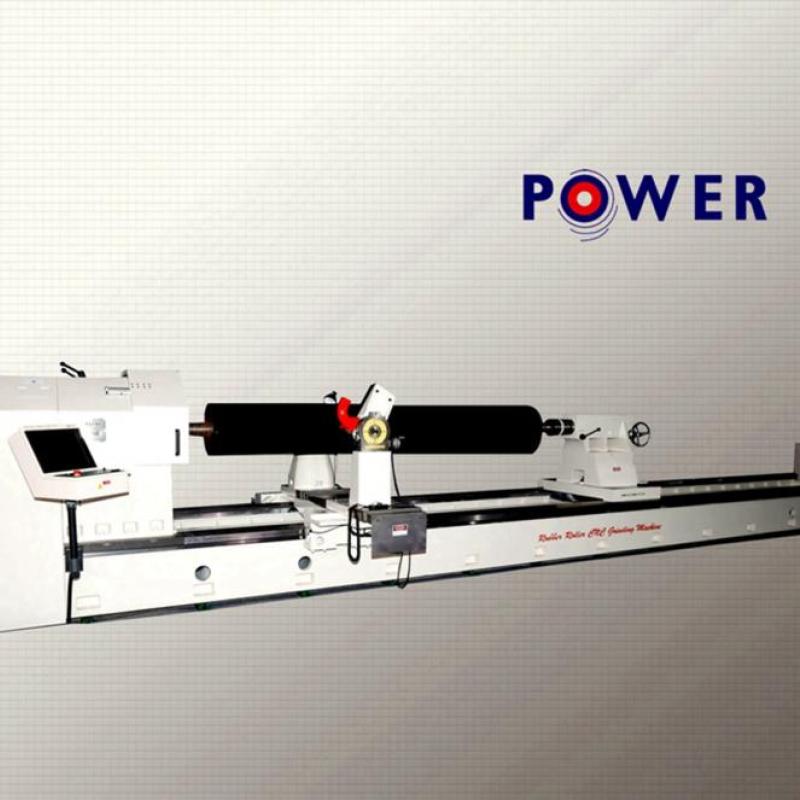

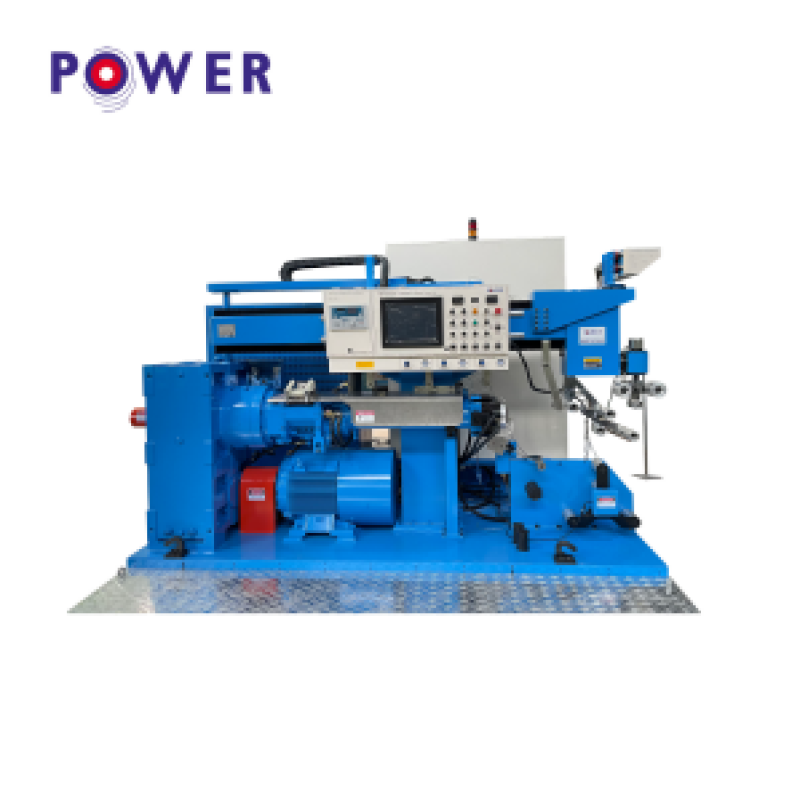

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contact Now

Textile Printing RollerPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

PRODUCTIONBeing extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality. Our products have sophisticated production technologies and excellent product quality, being recognized by domestic and foreign users.

Contact Now

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contact Now